Valves used in the oil and gas Industry

BROWNFIELD communicates on a daily basis with valve manufacturers and distributors here in Europe and other locations around the world. Quoting clients on a wide array of valves – safety relief and industrial from the best known manufacturers and the brand of our sister company Maverick Valves Netherlands.

■ BUTTERFLY VALVES

■ BALL VALVES

■ CHECK VALVES

■ CHOKE VALVES

■ CONTROL VALVES

■ CRYOGENIC VALVES

■ PLUG VALVES

■ GATE VALVES

■ GLOBE VALVES

■ PIG VALVES

Butterfly valves

BROWNFIELD offers a complete butterfly valve line to provide optimal performance our complete range of butterfly valves extend from general purpose to severe service models used for isolation and throttling applications.

It includes resilient seated valves for long service life and bubble tight shutoff; high performance valves capable of temperatures from cryogenic to as high as 815°C and pressures to ASME Class 1500 (PN 260); double flanged valves in sizes up to NPS 72” (ON 1800) and lined valves suitable for highly corrosive liquids, gases and slurries.

|

With a robust construction and a high cycle life, these valves will lower your total cost of ownership. |

For a normal Butterfly, a Dual Offset, Triple offset or a Cryogenic BF, just try us.

VARIANTS

■ Double Offset

■ Triple Offset

■ Triple Offset Top Entry

Size : NPS 2”- 72”

Pressure : Class 150# - 2500#

Structure Type : Flanged, Lug, Wafer, Long and short pattern, with inspection port

Face to Face Std : BS 5155, API 609, MSS SP-67, MSS SP-68

Test Standard : IS0 5208, BS 6755, API 598

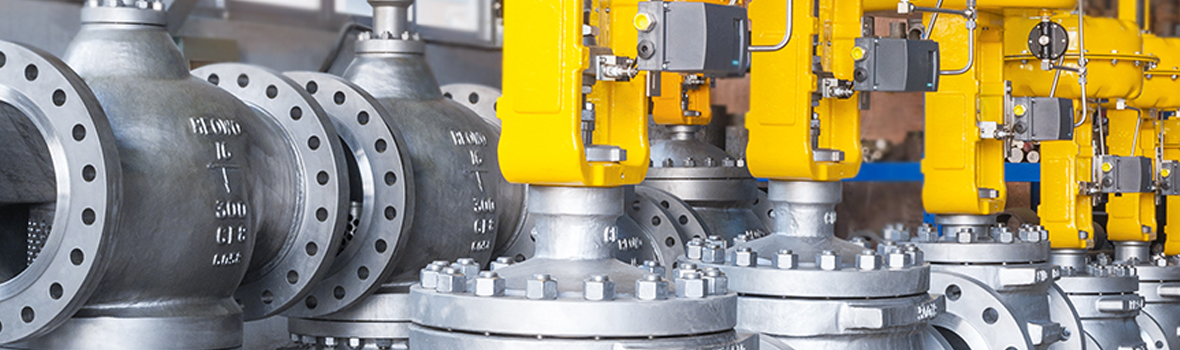

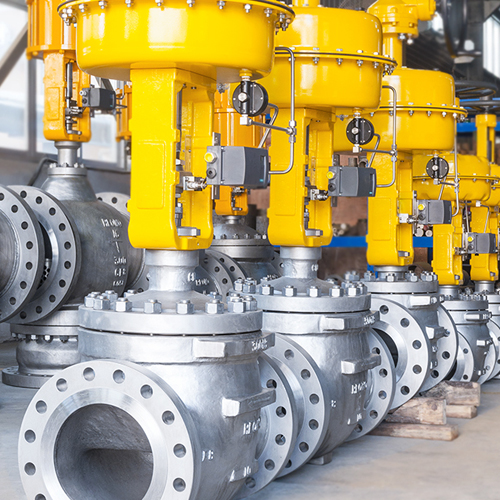

Ball Valves

VARIANTS

■ Trunnion ball valves side entry split body

■ Trunnion ball valves fully welded body

■ Trunnion ball valves side entry modular body (dbb)

■ Trunnion ball valve top entry

■ Cage ball control valve model lowcav / lownoise

■ Trunnion ball valve multiple way

■ Floating ball valves

■ Pig launcher ball valves

Size : Two or Three piece bolted body ½” - 56”

Pressure : Class 150# - 2500#

Port : Reduced bore, full bore or fully piggables

Stem retention : Anti blow-out stem

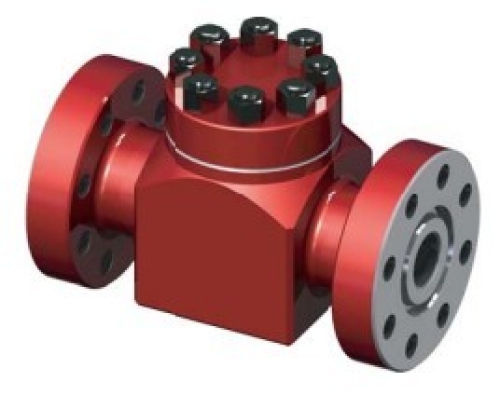

Check Valves

Our Check Valves are offered in various versions to meet the application specifications.

Our Check Valve versions include swing check valves, piston check valves, dual plate check valves, Axial check valves, and tilting disc check valves.

Check valves are designed to meet requirements of ANSI B16.34, BS-1868, ANSI B16.5, ANSI B16.10, API 602, API 6D and/or API 6A.

VARIANTS

■ Swing Check Valve

■ Tilting Disc Check Valve

■ Dual Plate Check Valve

■ Axial Flow Check Valve

■ Piston Check Valves

Size : NPS 1/2”- 36” and from 1.13/16” to 13.5/8”

Pressure : Class 150# - 2500# and from 2000Psi to 15000Psi

Structure Type : Regular Pattern, Pressure Sealed Pattern, Damping Pattern, Full bore

Face to Face Std :API 6D, API 6A, ASME B16.10, DIN 3202

Test Standard : IS0 5208, API 6D, API 6DSS, API 6A, API 598

Choke Valve Technical Summary

The External Sleeve Choke type is designed to provide precise flow control throughout its entire operating range. This choke has a cage and an external sleeve trim and is suitable for single or multiphase liquid and gas service.

Typical applications include Christmas trees, manifold, water injection and gas lift. The standard flow characteristic is equal percentage, but upon request can be supplied also the linear characteristic. These valves can be easily converted from manual to actuated valves using an adapter flange and electric, hydraulic & stepping actuator etc.

■ Pressure rating up to 15000 psi

■ Temperature range from -50° F to 350° F (-46°C to 1 n°c)

■ Trim sizes from 64/64” to 512/64” ( 1” to 8”) with controllable Cv from 1 up to 1000.

■ Meet or exceed API 6A / 170, NACE MR-01-75/ ISO 15156 and NORSOK requirements.

STANDARD FEATURES

The Cage with external sleeve design configuration directs flow through various sized ports opposite one another, forcing the flow to impinge upon itself within the nozzle, thus dissipating the fluid energy onto itself. With this design the turbulence and jetting are dissipated before flow enters the outlet, thus eliminating the typical problem of wear in the choke outlet. The Cage is the hardest component of the valve and typically is made from various grades of tungsten carbide. However, for less severe applications, other materials are available.

TRIM DESIGN FEATURES

Available of both plug and cage and external sleeve trims provides maximum flexibility and lower cost over the life of the field.

■ Trim ports geometry design reduces wear, tear and noise, maximizes flow and controls pressure throughout the operation range

■ Pressure balance stem and thrust bearing reduce torque, allowing minimized stem loads and actuation requirements

■ Thickness section of tungsten carbide resistance and reduced wear

■ Robust metal outer cage protects internal components from slugged flow or impact from entrained solids

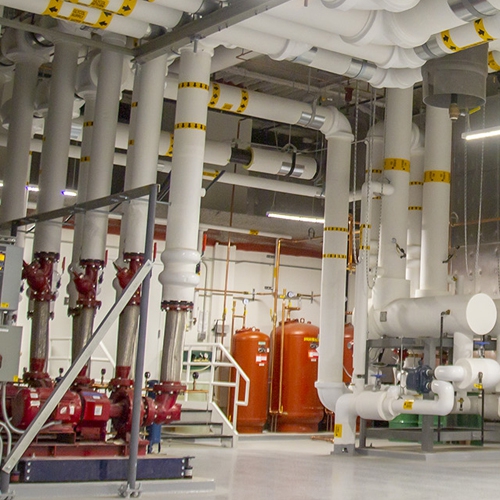

High Quality control valves

BROWNFIELD can supply high-quality control valves, with a focus on Globe Valves, Eccentric Plug Valves, and High-Performance Butterfly Valves.

We manufacture our Control Valves in The Netherlands in the Plant of our sister company Maverick Valves or supply other brands if you require.

Brown field Strengths

|

BROWNFIELD STRENGTHS ARE: |

|

|

■

Short response and delivery times ■

Custom made engineered products & solutions ■

Field support, installation, repair, maintenance & specialised services ■

Problem solving abilities |

|

|

Valve

Applications: ■

Flow Control ■

Temperature Control ■

Pressure Control ■

Level Control ■

Mixing & Diverting ■

Steam cooler |

Valve Types: ■

Globe type ■

Angle type ■

3-way type ■

Desuperheater Valves ■

Butterfly Valves ■

Regulating Ball Valves |

|

Valve Trims: ■

Severe services ■

Anti-Cavitation ■

Cavitation Control ■

Flashing Services |

Valve

Operation: ■

Globe type ■

Manually Operated ■

Pneumatic Actuated ■

Hydraulic Actuated ■

Electric Actuated |

|

Materials (Most

Common): ■

Carbon Steel ■

Stainless Steel ■

Duplex |

|

Cryogenic Valves

LIQUEFIED NATURAL GAS

LNG is exactly what it says: the liquid form of natural gas. The process of liquefying is performed to reduce the volume for purposes of transporting the fuel: LNG reduces volume by 600 times, making it much more economical to transport.

CRYOGENIC APPLICATIONS

When it comes to temperatures below -162° C the industry talks about cryogenic applications. We find these temperatures in different applications like air separation plants, chemical plants or LNG plants.

MATERIALS

The cooperation with primary quality European suppliers of gaskets and seals allow to keep FE levels to the highest standards, with a wide range of certification for all gasketing material (SHELL MESC 85-103, 85- 200, 85-203, 85-204, API 622, LI TP PVA 001, ISO 15848): For cryogenic service the material selection is ranging basically between austenitic stainless steel up to CRAs. Refer to our catalogue for a wide material listing and related allowable working pressure.

VARIANTS

■ Ball Valve

■ Check Valve

■ Gate Valve

■ Globe Valve

■ Triple Offset Butterfly Valve

Plug Valves

A Plug Valve is a quarter-turn rotational motion Valve that use a tapered or cylindrical plug to stop or start flow. In the open position, the plug-passage is in one line with the inlet and outlet ports of the Valve body. If the plug 90° is rotated from the open position, the solid part of the plug blocks the port and stops flow.

Plug valves are similar to Ball valves in operation.

TYPES OF PLUG VALVES

Plug valves are available in a non-lubricated or lubricated design and with several styles of port openings. The port in the tapered plug is generally rectangular, but they are also available with round ports and diamond ports.

VARIANTS

■ Inverted Lubricated Plug Valve

■ Dual Expanding Plug Valve

Size : NPS 1/2” - 32” and from 1.13/16” to 9”

Pressure : Class 150# - 2500# and from 2000Psi to 15000 Psi

Structure Type : Short Pattern, Regular Pattern, Venturi Pattern, Full Bore Pattern

Face to Face Std : API 6A/ ASME B16.34

Test Standard : IS05208, API 6D, API 598

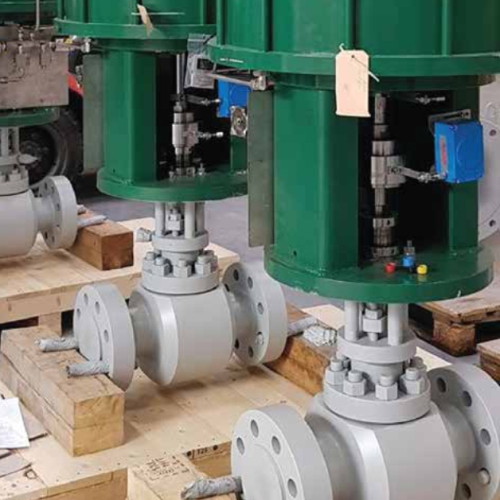

Gate Valve

A gate valve is a bi-directional valve, as the fluid may flow in either direction. The installation of this type of valve creates a modest pressure drop in the pipeline, lower than globe valves. Gate valves in general have forged bodies for bore sizes below 2 inches (API 602/BS 5352), and cast bodies for larger sizes (API 600, API 603, API 6D).

|

We can also offer the larger sizes in Forged execution if required. |

VARIANTS

■ Wedge gate valves

■ Parallel slide gate valves

■ Through conduit gate valves

■ Expanding gate valve

■ Fabricated gate valves

Size : NPS 1/2”-36” and from 1.13/16” to 9”

Pressure : Class 150# - 2500# and from 2000 Psi to 15000 Psi

Structure Type : Parallel slide, expanding, dual expanding, slab, through conduit, bolted bonnet, pressure seal

Face to Face Std :API 6D, API 6A, ASME B16.10,

Test Standard : IS0 5208, API 598, API 6D, API 6A

Globe Valves

This type of valve is used to throttle (regulate) the fluid flow. Globe valves can also shut off the flow, but for this function, gate valves are preferred.

A globe valve creates a pressure drop in the pipeline, as the fluid has to pass through a non-linear passageway. Nonetheless, a large number of variations exist, depending on the following factors:

■ Body material: cast (BS 1873) and forged (API 602/BS 5352)

■ Bonnet design: standard or pressure seal type (for high-pressure applications)

■ Bonnet to body connection: 60 bolted or welded

■ Valve end connections type: flanged (as shown in the image), butt-weld, socket weld/threaded (forged bodies)

■ Disc type

■ Stem type (rising/non-rising)

■ Seal type: conical or flat

■ Specification: BS, API, EN

■ Type of actuation: manual, with a gearbox, with an actuator

VARIANTS

■ Globe Valve

■ Globe Dual Seat

■ Control Globe Valve

Size : NPS 1/2” 36”

Pressure : Class 150# - 2500# 2000 to 15000 Psi

Structure Type : Parallel slide, expanding, dual expanding, slab, through conduit, bolted bonnet.

Face to Face Std :API 6D, API 6A, ASME B16.10,

Test Standard : IS0 5208, API 598, API 6D, API 6A

Piping Scrapper Valves

PIGGING - SCRAPER Valves combine the advantages of the Top Entry Ball Valve, and in addition to classic applications function as shut-off valves for pigging insertion or removal valves. The pig can now be inserted or removed through the interlock.

|

The advantages of the Pig/Scraper valves are primarily: Simpler operation, secure handing, reduced footprint, lower investment costs in comparison to traditional pigging interlocks |

Size : 2” - 24”

Pressure Class :150# - 2500#, 2000 PSI to 15000 PSI

Design Standard : ASME B16.5, ASME B16.25, API 6D

Face to Face Std : Manufacturer standard

Test Standard : IS0 5208, API 6D, API 598

APPLICATION

MVM-Pig/scraper Valves permit simple and quick launching and receiving of pipe cleaning and separating pigs as well as short pipe scrapers. The advantage of the Pig Valve in comparison with conventional pig traps lies in simple operation and pipe runs as well as reduced space requirements through short overall lengths.

To permit pig launching and receiving, the valve housing has a trap at the side which is equipped with a closure. The design of the MVM Pig Valve is, except for the additional trap, indentical with the MVM Top entry Ball Valve.

■ Top Entry Design, i. e. the ball and seatrings are fitted into the valve body from the top, thus for repair work there is no need to remove the entire valve fitting from the line.

■ All component parts can be fitted without the need for special tools.

■ The through-bore has no gaps or shoulders in which foreign matter can settle.

■ All seals feature simple geometrical shapes, e. g. 0-rings.

■ Maverick Valves is permitted to use the official API monogram on pipeline valves. Thus, materials, inspection and dimensions follow the API Spec 6D.

BrownField Trading & Contracting

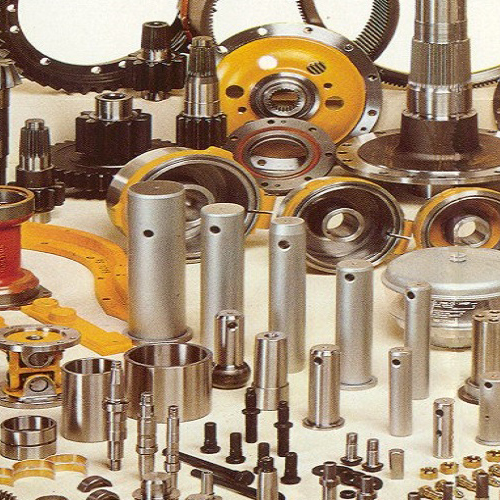

Spare Parts

Spare Parts

We are supply steel products piping materials. to engineering contractors and operators in the oil, gas, petrochemical

Structural Steel

Structural Steel

We are supply steel products piping materials. to engineering contractors and operators in the oil, gas, petrochemical

Instrumentation Bulk

Instrumentation Bulk

We are supply steel products piping materials. to engineering contractors and operators in the oil, gas, petrochemical

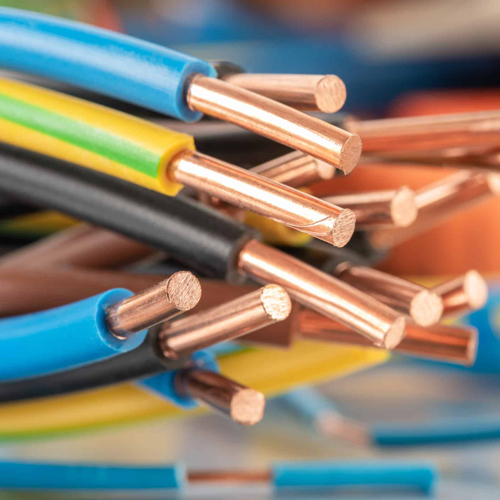

Electrical Cable & Equipment

Electrical Cable & Equipment

We are supply steel products piping materials. to engineering contractors and operators in the oil, gas, petrochemical