Gasket

GASKETS

■ Spiralwound

■ Ring type joint

■ Metal jacketed

■ Graphite

■ Camprofile

■ PTFE steel lined

■ Jointing material

METAL JACKETED GASKETS

Features

Metal-jacketed gaskets are produced in a wide variety of different materials (in various combinations), in many cross-sections and in many styles. They are suitable for flanges in heat exchangers, pipe flanges, boilers and process equipment.

DESIGN

Metal-jacketed gaskets consist of:

■ Metallic outer shell with an asbestos-free filler

■ The filler material gives the gasket resilience

■ The metal jacket protects the filler and resists pressures, temperatures, and corrosion

MATERIALS OF CONSTRUCTION

Filler materials

Non-asbestos fiber sheet, NBR/aramid fiber sheet, Graphite, Ceramic Metal jacket materials Soft Aluminium, Soft Copper, Brass, Carbon steel, 304 or 304L stainless steel, 316 or 316L stainless steel, 321 stainless steel, Hastelloy® B2 or C-276, Inconel® 600, Monel® 400 Other metals and alloys available on request.

Ring joint gaskets

BROWNFIELD supplies a large variety of ring joint gaskets. The RTJ standard size gaskets are manufactured in accordance to API-6A and ASME B16.20 specifications. Total control of manufacturing processes ensures correct gasket surface and hardness to give a good seal without damaging flange connections. The hardness of the ring should always be less than the hardness of the flanges to prevent flange deformation. The sealing surfaces on the ring joint grooves must be smoothly finished to 63 microinches.

DESCIPTION OF AVAILABLE SECTIONS

API ring Joint gaskets come in two standard types, an oval cross-section, and an octagonal cross section. These standard shapes are used in pressures up to 10,000 psi. The dimensions are standardized and require specially grooved flanges.

■ Type R octagonal – Octagonal and Oval configurations are interchangeable on flat-bottomed groove flanges that have a 23° angle groove wall.

■ Type R oval – An oval ring joint flange that was designed for a flange that is now out of production. This flange had a rounded bottom ring groove. Oval and octagonal configurations are interchangeable on flat-bottomed groove flanges that have a 23° angle groove wall.

■ Type RX –RX is a gasket designed for pressures up to approx. 700 bar. This is a self-sealing gasket that uses a pressure-energized effect, which improves the efficiency of the seal as the pressure rises. The RX series is interchangeable with the R series.

FEATURES

Ring type joints are manufactured according to ASME B16.20 (2007) standards and to API specification 6A and 17B. Total control of manufacturing processes ensures correct surface hardness to give a good seal without damaging flange sections. Type BX– BX is a gasket designed for very high pressures up to approx. 1,500 bar. These rings may only be used in connection with API type BX flanges and grooves. The BX ring has a through horizontal hole that acts as a pressure equalizer.

Type SRX and Type SBX – Type SRX and SBX gaskets per API 17D for Subsea Wellhead and Tree Equipment are vented to prevent pressure lock when connections are made up underwater. They have identical measurements to RX and BX ring gaskets with the same number designation, and they will fit the same corresponding connectors.

The “S” indicates these gaskets have cross-drilled holes, as fluid entrapment in the ring groove can interfere with proper makeup underwater (subsea). With the vent hole, any water trapped between a ring groove bottom and the sealing area of the gasket can escape to the equipment I.D. bore. Material per spec is defined as a corrosion resistant alloy.

IX Seal Ring gaskets – The IX-rings are designed and used where the NORSOK CFC (Compact Flange Connections) are in use. The rings come in three different kinds of steel and are coated with PTFE in varying colors in order to distinguish between them. Standard identification NORSOK STANDARD L-005 (NCF5). All markings should be on the inside of the ring.

RTJ GASKETS AVAILABLE IN THE FOLLOWING MATERIALS

■ Soft iron

■ Low carbon steel

■ F-5

■ AISI 304

■ AISI 316

■ AISI 316L

■ AISI 321

■ AISI 347

■ Duplex S31803

■ ALLOY 825

■ AISI 316L with a hardness of HB 135 max

Other materials on request

Spiral Wound Gaskets

The sealing element of the spiral wound gasket consists of a v-shaped metal strip spirally wound in combination with a soft sealing material filler. The metal strip provides outstanding resilience, while the flexible sealing filler guarantees excellent sealing. Due to this combination of materials the spiral wound gasket is suitable for sealing under severely fluctuating temperature and pressure conditions. Depending on the application the spiral wound gasket can be specified with outer and/or inner rings.

CHARACTERISTICS

■ Metallic outer shell with an asbestos-free filler

■ The spiral wound gasket is suitable for use across a wide pressure range and is therefore virtually applicable.

■ The spiral wound gasket can be used to seal fluid pressures up to 250 bar and damage (although extra care should be taken during transportation and installation of large diameter gasket without guide rings).

■ The outer guide ring serves to locate the spiral element central on the flange faces and prevent blow-out.

■ By combining different winding materials and metals the gasket can be tailored to a wide variety of operating conditions.

■ Due to its non-adhesive character the gasket is easy to remove after service.

■ The gasket does not cause damage to the flange faces

BENEFITS OF THE OUTER CENTRING RING

The spiral wound gasket outer centring ring provides the following benefits:

■ Optimum location between the bolts.

■ Protection of the spiral wound element.

■ Additional security against gasket blow-out.

■ Acts as compression limiter preventing overloading and overcompression of the spiral wound element.

■ Prevents radial-flow of soft fillers, such as P.T.F.E.

For these reasons it is preferable to use spiral wound gasket with outer centring rings. The the outer ring is marked with nominal size, pressure class, standard and materials.

BENEFITS OF THE INNER CENTRING RING

The spiral gasket inner ring provides the following benefits:

■ Prevents radial-flow of soft fillers, such as P.T.F.E.

■ Reduces turbulence-minimising flow resistance and crevice corrosion.

■ Acts as a heat shield when the spiral wound gasket is subjected to high temperatures.

■ Avoidance of over-compression at elevated seating loads in high-pressure service

■ Improvement of the load distribution over the gasket Inner and outer rings are particularly recommended for use on spiral wound askets exceeding class 600lbs, but specifically recommended for high temperatures and Pressures to optimise the operational reliability of the spiral wound sealing element.

BrownField Trading & Contracting

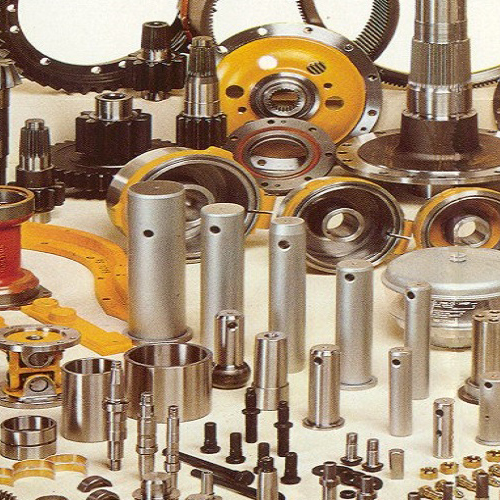

Spare Parts

Spare Parts

We are supply steel products piping materials. to engineering contractors and operators in the oil, gas, petrochemical

Structural Steel

Structural Steel

We are supply steel products piping materials. to engineering contractors and operators in the oil, gas, petrochemical

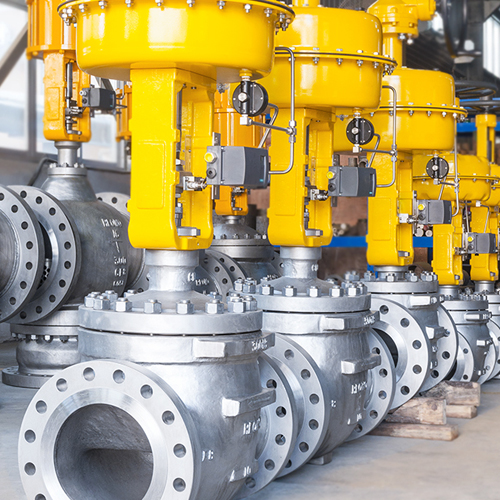

Instrumentation Bulk

Instrumentation Bulk

We are supply steel products piping materials. to engineering contractors and operators in the oil, gas, petrochemical

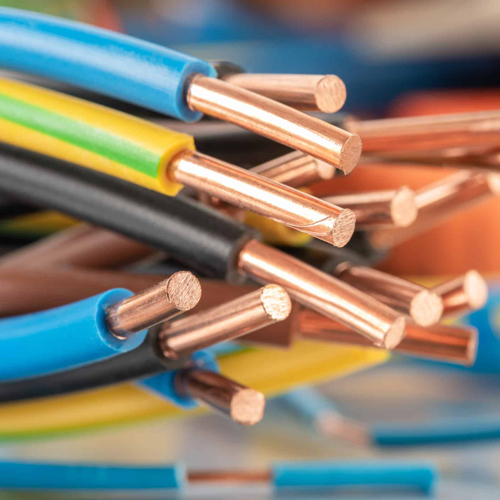

Electrical Cable & Equipment

Electrical Cable & Equipment

We are supply steel products piping materials. to engineering contractors and operators in the oil, gas, petrochemical